Vessels are used to store a variety of materials – the cladding must be in good condition

Small vessels are used for the intermediate storage and preservation of raw materials, auxiliary products, or end products such as water or other liquids in industrial processes. In industry, vessels also relieve pressure by transferring pressure from one vessel to another.

Regardless of what is stored in the vessel, it is essential to ensure that the cladding and the insulation keep the stored material either hot or cold and meet safety requirements. A suitable quality cladding will also protect the insulation in the vessel and make it last longer.

Small vessels are vertical or horizontal vessels standing on legs. The insulation of vessels is critical as the temperatures of the contents of the vessels are usually high, as is the process itself, resulting in increased heat loss in the vessel. Sometimes, the temperature of the contents to be stored in the process vessel must not drop too much, in which case good insulation is also essential.

Claddings for small vessels are made to customer requirements

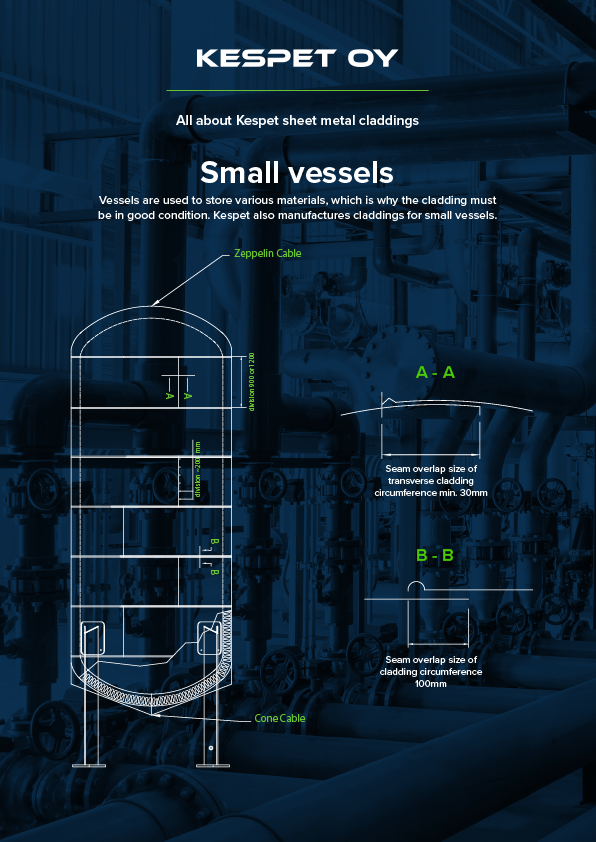

The insulation of a small vessel consists of a cladding of support structure, insulation, and a cladding. We manufacture vessel liners from all standard materials, ready-perforated and with beadings according to the vessel measurements. The vessel cladding section is coated with a vessel cladding made of smooth sheet metal with a 100 mm overlap as standard and a minimum overlap of 30 mm in the screw/rivet fixing joint. The vessels are manufactured with attention to the joints so water cannot penetrate the insulation.

Kespet’s small vessels’…

- sheet metal cladding options for the ends are zeppelin gable or cone gable

- variety of jointing possibilities, depending on the location and size of the vessel

- 20 mm support for the vessel cladding can also be manufactured.